From laser 3D printing to an antibody treatment for whooping cough, two industry-changing ideas started by asking the right questions and chipping away at the solution.

“Engineers solve problems and they solve them one by one,” says Professor Joseph Beaman, a mechanical engineer who invented selective laser sintering, a form of 3D printing. “I always tell my students engineering is really easy, because every problem we solve isn’t that difficult. The problem is you have to solve so many, and they all have to work.”

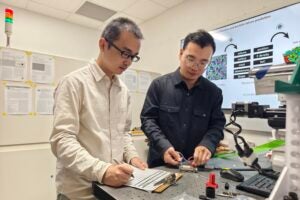

Beaman and chemical engineer Jennifer Maynard were honored Nov. 18 as the 2015 Inventor of the Year and Emerging Inventor of the Year, respectively. The awards from the Office of Technology Commercialization recognize researchers whose inventions and innovations have made substantial contributions to the world.

Past Inventor of the Year recipients stand behind other important technologies, such as the revolutionary lithium-ion battery used to power an array of consumer electronics and the use of therapeutic proteins to help fight cancer.

2015 Inventor of the Year: Joseph Beaman

If you walk around the engineering complex on campus, it is hard to imagine a world before 3D printing. The technology is widely accessible for professors and students to 3D print prototypes, designs and gadgets. There is even a 3D printing vending machine, the Innovation Station, in the highly trafficked Engineering Teaching Center (ETC).

But in the 1980s, the idea of creating an object from a three-dimensional computer design using a single machine was nearly inconceivable. Mechanical engineering professor Joseph Beaman saw the potential of combining computers and lasers to improve additive manufacturing.

“We knew early on that if we could do it, it would essentially change the way people did manufacturing,” Beaman says of the collaboration with his then-graduate student Carl Deckard. In 1986 they invented one of the first forms of 3D printing — selective laser sintering (SLS).

[Read more – Selective Laser Sintering: Birth of an Industry]

Over the past 30 years, SLS has improved its speed and precision dramatically, but the concept remains the same. Like the pyramids in Egypt, objects created by SLS are built one layer at a time. The SLS machine zaps a paper-thin layer of dust with a laser to form 3D objects from the powder.

“The SLS machine is all operations in one machine, really, because essentially there’s only one operation — it’s adding stuff” rather than carving stuff away, says Beaman, who holds the Earnest F. Gloyna Regents Chair in Engineering.

Unlike the simpler 3D printing machines in maker studios, SLS has been used to create usable parts for airplanes, race cars and medical devices. Not only is it fast, but it offers manufacturers unlimited customization.

[See how today’s engineering students are using 3D printing technology to bring their ideas to life.]

“What if you could take an MRI of the brain, know what the tumor shape was and automatically design the cathode delivery system that could provide just the right amount of medicine? [Put it] just where you want it to be, in the right shape, and build it that day and have it next day,” Beaman explains. “That’s the kind of thing we’re talking about.”

Figuring out how to execute complex designs was a cross-disciplinary effort.

“I’ve never been the person to say I have to do it all,” Beaman says. “What I like about UT is it doesn’t have very big silos. To make this work we had to have people over at chemical engineering, electrical engineering and computer science.”

“What you were taught before, as a mechanical engineer, is you do not want to have a whole lot of complexity in your design because you have to machine it,” Beaman says. SLS changed that paradigm. Now he says, “If you can imagine it, we can build it.”

Emerging Inventor of the Year: Jennifer Maynard

Pertussis, or whooping cough, is a disease that claims the lives of 195,000 children across the globe annually. Jennifer Maynard, an associate professor in the McKetta Department of Chemical Engineering, is on the cusp of a treatment.

While working on her Ph.D. research to create an antibody to neutralize anthrax toxins, Maynard realized a similar technique could be used to fight pertussis. She is testing a therapeutic injection to treat the symptoms of pertussis and the painful coughing fits that come with the illness.

Maynard’s “passive” immunizations give babies who’ve had exposure to pertussis “instant immunity” using a mixture of two antibodies. The first binds to the whooping cough toxin, preventing it from attaching to healthy cells. The second stops the toxin from reaching its target within a healthy cell.

“It gives this one-two punch to deal with the toxin,” says Maynard, who was named 2015 Emerging Inventor of the Year. The therapeutic can also help babies who have contracted the disease by easing their symptoms while antibiotics work to eliminate the bacteria that causes the illness.

Maynard is working with Synthetic Biologics to bring her solution to the market, paving the way for public use in only a few years. She is optimistic her vaccine will soon reach the people who need it most, possibly even being distributed for free in developing counties.

“We want to make sure that whatever we come up with at the end is really going to have impact,” Maynard says.

This story is part of our “Eyes on Innovation” series, which explores UT’s world-changing ideas, fascinating discoveries and new ways of doing things.