AUSTIN, Texas—Consumers may be able to purchase more affordable computers and electronics due to an innovative alliance between Advanced Micro Devices and The University of Texas at Austin. The alliance seeks to improve the production of semiconductors to lower production costs and potentially lower the price of electronics.

Dr. Joe Qin, a 36-year-old assistant professor in the Department of Chemical Engineering at the University of Texas at Austin, plans to use his National Science Foundation Early Career Development (CAREER) Award of up to $300,000 over four years to further the research alliance between the university and Advanced Micro Devices (AMD). AMD is a global supplier of integrated circuits for the personal and networked computer and communications markets.

The alliance gives university researchers access to AMD’s manufacturing equipment and data and is aimed at improving detection and repair problems that currently slow semiconductor production, driving up costs. The U.S. Department of Commerce reports that up to 40 percent of manufacturing revenues are spent on maintenance and management of problems such as malfunctioning sensors or machinery.

Streamlined semiconductor production has become increasingly important for semiconductor wafer quality as economic competition demands smaller integrated circuit chips cut from larger wafers. “The bigger the wafer, the more chips that can be manufactured, improving yield and efficiency,” said Qin. He said the dimension is always shrinking for each chip because they always want faster speeds for computers.

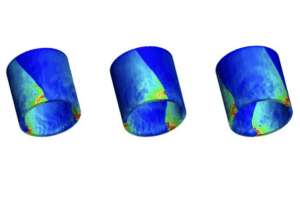

Qin said uniformity between wafers and chips is harder to achieve as wafers get larger, because the processes used on them are harder to control over a larger surface. He said variations between each wafer contribute to about 50 percent of discarded semiconductor materials.

Qin proposes to improve the process by providing maintenance as needed — versus maintenance as scheduled. Improved monitoring equipment for faster response times is the first step in his plans.

“We use optical emission sensors to tell more about what’s going on, so we can detect problems if there are any and can detect when the process has stopped,” Qin said. He said that prompt detection of the interruptions could reduce the time and wafers lost.

Qin said he and his colleagues also would use advanced statistical methods to analyze information from all the different steps of the manufacturing process. “There are normally hundreds of steps in making an integrated circuit. You have to make sure that each step is correct so that the final product will be of good quality,” he explained.

Qin will be developing these advanced analysis methods in conjunction with the advanced process control group of AMD’s FAB 25 manufacturing facility, where AMD produces the AMD Athlon (ó) Microprocessor.

National Science Foundation CAREER awards are intended to assist young faculty members in developing their teaching skills, and Qin also has been a pioneer of innovative teaching at UT Austin.

Dr. John G. Ekerdt, chair of the Department of Chemical Engineering, said: “Dr. Qin has a pivotal role in teaching and research activities within our chemical engineering department in the process systems engineering area — an area that is at the core of our chemical engineering undergraduate and graduate education.”

Besides bringing together students and industry to provide students with practical experience, Qin has supported more updated curricula, employed multimedia and Internet-based course materials and encouraged female students to enter fields such as process monitoring and control which have traditionally been male dominated.

Qin received his Ph.D. in chemical engineering from the University of Maryland and has master’s and bachelor’s degrees from Tsinghua University in China. He joined the UT faculty in 1995 and received the UT Austin Engineering Foundation Faculty Excellence Award and the Department of Chemical Engineering Teaching Award in 1997 based on student votes and comments.

The National Science Foundation will increase its four-year CAREER grant by $25,000 per year if Qin matches that amount in industry contributions. AMD currently contributes $25,000 a year to his research. DuPont has pledged $25,000 a year for three years to apply Qin’s findings to chemical and polymer processes. AMD, AMD Athlon, K6 and combinations thereof are trademarks and AMD-K6 is a registered trademark of Advanced Micro Devices, Inc.

For more information, contact Becky Rische at the UT Austin College of Engineering at (512) 471-7272 or Dr. Joe Qin of the Department of Chemical Engineering at (512) 471-4417. For high resolution scans of Qin, contact Marsha Miller, Office of Public Affairs, at marsha@opa.wwh.utexas.edu or visit Website address /opa/news/00newsreleases/nr_200003/nr_qin.html.