AUSTIN, Texas— By discarding most of their favorite new technologies — including lasers, complex vacuum systems and 2,000-pound lenses — engineering faculty at The University of Texas at Austin have created a process with the potential to make the smallest, fastest and cheapest computer chips.

Led by Dr. Grant Willson, professor of chemical engineering and chemistry at UT Austin, the engineering research team developed a radically different process for patterning semiconductor devices. Their new method uses simple molds and operates at the old-fashioned conditions of low pressure and room temperature.

They call their process “Step and Flash Imprint Lithography.” Graduate students studying under Willson will present the team¤s findings at the International Conference on Electron Ion and Photon Beam Technology and Nanofabrication in Palm Springs today (May 31).

Wilson led research groups at IBM, and later at UT Austin, that were responsible for several major breakthroughs in lithography during the last 20 years. Other faculty on the team include Dr. S.V. Sreenivasan, associate professor of mechanical engineering, Dr. John Ekerdt, chairman of UT Austin¤s department of chemical engineering, and Dr. Jack Wolfe, professor of electrical engineering at the University of Houston.

“Their process has some amazing inherent advantages,” said David Markle, vice president and chief technical officer of Ultratech Stepper. “It is essentially unlimited in terms of resolution, unlike current tools, and it is potentially very cost effective.”

While laboratories worldwide have many adaptations of imprint lithography under study, Step and Flash Imprint Lithography is the only imprint process based on reactions that occur at room temperature and low pressure, Willson said.

“The new process has the potential to achieve the precision over lay (layer to layer alignment) required to manufacture advanced devices, since the template is transparent and rigid and the work pieces are not subjected to either high temperatures or high pressures that could distort them,” Willson said.

The success of the semiconductor manufacturing industry is, to a significant extent, the result of learning how to make circuits smaller. Smaller devices are inherently faster and cheaper to produce. The step in the chip manufacturing process that controls the device size is microlithography.

This printing process involves projecting the circuit design from a master “mask” onto a wafer coated with a photosensitive material called a photoresist. The ability to print ever-smaller device structures in the photoresist requires ever more sophisticated cameras called projection printers. The most advanced projection printers use very sophisticated lasers as a light source, and they have lenses with as many 30 individual elements. These lenses are made of highly specialized glass and weigh nearly one ton. One projection-printing tool now costs approximately $10 million and the cost of these tools is increasing exponentially with time, said Willson.

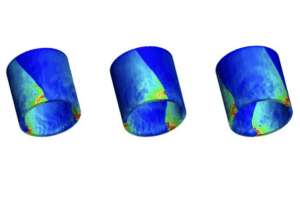

The Texas team¤s new process is based on production of a rigid, transparent, quartz template patterned with a relief structure (grooves). High-resolution templates for the process are made by existing technologies and samples have been provided by the RTC, Etec Systems and IBM. The template is brought into contact with a layer of two thin polymer films coated on the wafer surface by traditional means.

The lower layer is a common polymer coated with a low viscosity, organo-silicon liquid called the etch barrier. When the template is brought into contact with the polymer coating, the liquid etch barrier material is trapped in the relief structure of the template. Ultraviolet light then is flashed through the transparent template and serves to harden the etch barrier material in a process very similar to that used to fill cavities in modern dental practice. The template then is removed to leave a replica of the relief structure on the wafer. The imprinted relief pattern can then be etched by traditional means to produce the high aspect ratio, high-resolution images required to manufacture advanced devices.

Their research was sponsored by the Semiconductor Research Corporation and the Defense Advanced Research Projects Agency and assisted by collaborations with SEMATECH, Agilent Technologies, 3M Corporation, the Reticle Technology Center of Dupont Photomask, Ultratech Stepper and IBM.

UT Austin chemical engineering graduate students Matthew Colburn, Todd Bailey and Michael Stewart assisted with the research, along with mechanical engineering post-doctorate Byung Jin Choi, mechanical engineering graduate student Michael Kerwic and University of Houston electrical engineering graduate student Paul Ruchhoeft.

Note to Editors: High-resolution photos may be found atwww.utexas.edu/admin/opa/news/00newsreleases/nr_200005/nr_chips2.html