AUSTIN, Texas—Dr. Thomas Truskett, assistant professor of chemical engineering at The University of Texas at Austin, has received a five-year, $625,000 David and Lucile Packard Fellowship in Science and Engineering.

Truskett and his research group have a two-part mission: to develop techniques to study the properties of nano-sized glassy materials used, for example, in high resolution printing or biomedical applications and to create “smart” methods of predicting protein behavior for both drug development and disease prevention.

For the glassy nano-materials portion of the research, Truskett explains that “economics is now driving the understanding of properties of materials at small length scales. If we want to make smaller, faster computer chips, biomedical devices, etc., we have to understand what happens at this tiny scale.”

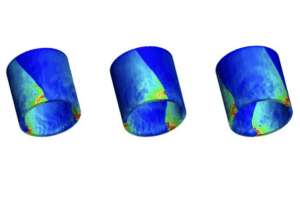

Discovering what makes glassy materials stable, and predicting how they will fail under stress at the nano-level is particularly difficult. This is partly because the atoms in glassy materials are arranged randomly, which makes it difficult to identify potential defects. To make matters worse, the properties of glasses change depending on how they are made, unlike common crystalline materials.

The researchers will create new theories and computer models of how the molecules in glasses interact with each other, and use what they learn to predict the material’s behavior.

“If you understand how a material works in its internal structure,” Truskett says, “you’ll be able to create stronger materials more resistant to failure. You could create better circuits, better biomedical applications and much more. We’re only at the beginning of that trek.”

For the portion of the research devoted to proteins, the researchers will address the time-consuming problem of predicting protein behavior. This is so complex it requires a year for a supercomputer to model a protein folding into its final three-dimensional structure. The difficulty occurs because each protein is surrounded by water molecules that vibrate on a different time scale than the protein itself. As a result, every time the protein moves a detectable amount, each water molecule has vibrated many times. Because of the time this takes, it is impossible to see how millions of them interact in solutions.

To solve the problem, Truskett’s research team will try to mathematically “smear” out the water molecules and make a sort of “low-resolution” model that leaves out the unnecessary information but still accurately shows the protein’s behavior. If done correctly, engineers and scientists could watch processes like protein folding and aggregation within a day or week.

Predicting protein behavior in different solutions will greatly benefit the pharmaceutical industry. Many protein solutions degrade because the proteins clump together, or aggregate. Knowing why and when they this happens could save money and time. In addition, neurodegenerative diseases such as Alzheimer’s or mad cow disease are related to proteins unfolding and aggregating. If engineers and scientists can determine how to prevent unwanted protein folding, they can more likely successfully treat these diseases.

For more information contact: Becky Rische, College of Engineering, 512-471-7272.