AUSTIN, Texas—Environmentally friendly concrete is the goal of the $400,000 National Science Foundation Faculty Early Career Development (CAREER) award granted Dr. Maria Juenger, civil engineering assistant professor at The University of Texas at Austin. The grant is one of the most prestigious awarded to young faculty members.

|

|

Dr. Maria Juenger, civil engineering assistant professor, was awarded $400,000 from the National Science Foundation to develop environmentally friendly concrete from waste materials.

|

“Anything we can do to make concrete more environmentally friendly will have a big impact,” says Juenger, “simply because it’s the world’s most used material.”

More than six billion tons of concrete are produced annually—about one ton per person on the planet. Concrete is made from cement, water, sand and gravel. The cement is made by heating raw materials such as limestone and clay to very high temperatures until they chemically react. This process uses massive amounts of energy (about five percent of the world’s use per year) and releases about a ton of carbon dioxide per ton of cement made.

Juenger proposes to make cement out of waste materials instead of new materials to reduce the carbon dioxide emitted and energy used for production. One such waste material is fly ash, a byproduct of the coal-burning industry. Fly ash is already used in concrete as a cement substitute and has a composition similar to cement.

“The idea is pretty simple,” says Juenger. “We’re making something new out of trash. We’re trying to save energy and prevent waste from piling up in landfills while making something people want and are going to use anyway.”

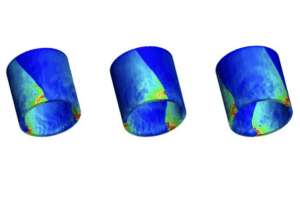

Once Juenger and her research group have found suitable raw-material substitutes for making cement, they have to make sure that the new cements perform as well as regular cement. They are confident their project will lead to major advances in making concrete a sustainable material.

For the educational component of the grant, Juenger plans to bring sustainable development and materials science concepts to elementary and middle schools.

“It’s a great way to teach students about science, and for them to learn about cause and effect,” she says. “We can teach them how to make their own concrete, how what they add will affect its properties and how the materials they see and use every day affect the earth.”

For more information contact: Becky Rische, College of Engineering, 512-471-7272.