AUSTIN, Texas—Dr. Yueh-Lin (Lynn) Loo at The University of Texas at Austin has received a 2005 Young Investigator Award from the Arnold and Mabel Beckman Foundation to find ways to improve the ability of polyaniline to conduct electricity.

Loo, an assistant professor of chemical engineering, will use the three-year, $264,000 award to seek a 10-fold increase in the conductive ability of the plastic. That enhancement might be enough for manufacturers to begin considering polyaniline-based wires for products that include: electronic display screens that can be rolled up after use, clothing with polyaniline woven into it that changes color when exposed to a harmful chemical, and implantable medical devices that release a drug when someone’s body temperature changes.

|

|

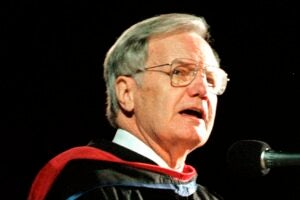

Dr. Yueh-Lin (Lynn) Loo, assistant professor of chemical engineering, in her research lab with students (left to right) James Norman, Joung Eun Yoo and Kwang Seok Lee, who are all part of the research team working to increase the conductive ability of plastics (polyaniline). Photo: Caroling Lee |

“Using this material to develop biodevices would be especially nice,” Loo said, “because polyaniline appears to interact well with living cells.”

Plastics involve long chains of carbon atoms, which traditionally are molded into the shell of hair dryers and other devices because plastics transfer heat and electricity poorly. Scientists make plastics electrically conductive through a process called chemical doping where another molecule that can donate charge to the plastic is added. Loo’s process is different in that the molecule that is added is a polymeric acid, which is larger than previous molecules tested.

Determining the right ratio of the two starting components needed to achieve good conductivity will be part of Loo’s general grant efforts to better understand how the final polyaniline’s features are influenced by the reaction processes involved in creating modified versions of it.

“The question is, ‘How do the nanoscale features of this plastic affect its macroscopic electrical properties,’” Loo said. “That’s important information to gain.

“When you make a device in the laboratory, it’s OK if it works one time, but you want the material’s properties to be reliable and reproducible before you can even think about big applications.”

Using polymeric acid also increases polyaniline’s ability to dissolve in water. Previous attempts to dope polyaniline to become metal-like failed because the final product would not dissolve in any solvents, which is considered crucial to making inexpensive products with it.

“Traditional doped polyaniline is as good as brake dust,” Loo said. “While it is fairly conductive, you cannot process it, so you can’t use it for anything.”

Loo plans to find the right ratio of polymeric acid to mix with the plastic so that an excess of the acid will be present along the polyaniline backbone. These extra acid molecules are thought to make polyaniline dissolve in water because they are available to interact with water molecules in the liquid the plastic is bathed in.

Loo has molded water-soluble polyaniline into wiring using a water-based process developed in her laboratory called the stamp-and-spin-cast technique. The patterning proceeds at room patterned silicon or other surface that attract water. The polyaniline is preferentially drawn to those regions when a solution of the plastic is added to the patterning surface. This is done while the surface is spinning, which evenly spreads out drops of the plastic.

Using this approach, Loo’s laboratory has manufactured micron-scale polyaniline electrodes and tested their ability to conduct electricity as part of transistors.

“We compared the device performance of these transistors to transistors with gold electrodes, and they work as well for all practical purposes,” she said.

Loo noted that polyaniline wiring won’t ever conduct electricity as well as gold or other metals. Nor is it possible to create polyaniline at the nanoscale dimensions, or with the uniformity, needed for it to be considered for wiring in next-generation microprocessors. The 10-fold enhanced conductivity she seeks, though, should suffice for the cheap, flexible, large-scale applications under consideration.

Loo is one of 24 recipients worldwide of this year’s Young Investigator Awards from the Beckman Foundation. Her other recent honors include being named one of Technology Review’s Top 100 Young Investigators for 2004, and receiving a National Science Foundation CAREER Award that year.

For more information contact: Becky Rische, College of Engineering, 512-471-7272.