AUSTIN, Texas—A biomedical engineer at The University of Texas at Austin has received a four-year, $1.05 million grant from the National Institutes of Health to begin analyzing a modified plastic for use to repair severed nerves in the body or to serve other medical purposes.

The plastic, called polypyrrole, is a man-made, electrically conducting plastic (polymer) with broad biomedical potential that has been successfully linked to a natural molecule so it can interact with nerve cells or other body components. Associate Professor Christine Schmidt and colleagues described this bioengineering feat in the June issue of the journal Nature Materials.

|

|

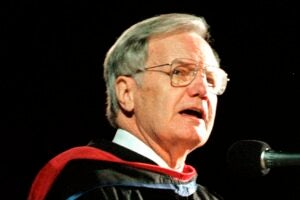

Dr. Christine Schmidt has received a four-year, $1.05 million grant from the National Institutes of Health to investigate the potential of a modified plastic to stimulate the regrowth of severed nerves in the body or to serve other medical purposes.

|

| Photo: Jennie Trower |

The study in the journal demonstrated that polypyrrole could attach to human cells grown in a container. That was possible because the polymer was first linked to a fragment of a protein that likes to interact with cells. The intermediary, linking fragment consists of 12 amino acids, and is known as the T59 peptide. The findings are important because Schmidt’s laboratory has previously shown that polypyrrole can stimulate nerve repair in animal models through its unusual ability to conduct electricity.

With the new grant, Schmidt’s laboratory will learn more about how polypyrrole and the T59 peptide interact, whether the polymer/peptide combination is harmful to body tissues and whether T59 can link large biomolecules to polypyrrole that could further stimulate nerve regeneration, prompt the release of signaling molecules between cells in the brain, or promote health in other ways.

“There are many possibilities for what we can now do with this polymer that we didn’t have in the past, and the question is, how can we really capitalize on its increased biocompatibility to create biologic/electronic materials that have good biomedical applications,” said Schmidt, who holds the Laurence E. McMakin Jr. Centennial Fellowship in Chemical Engineering.

To study how well T59 clings to polypyrrole in the first place, researchers will attach copies of the peptide to the tip of an atomic force microscope at the university’s Center for Nano- and Molecular Science and Technology. The tip of the specialized microscope usually is used to “map” the peaks and valleys on a surface it is passed over. Instead, Schmidt, postdoctoral student Joo-Woon Lee and graduate students Francisco Serna and Jonathan Nickels will use the microscope to see how well T59 coated on the microscope’s tip clings to a surface coated with polypyrrole.

In a more detailed test of the strength of their interaction, Schmidt’s laboratory will determine how well T59 containing a small amount of radioactive material attaches to other surfaces coated with polypyrrole.

The stability of the polymer/peptide interaction will also be investigated by seeing how much T59 peptide hangs around after injecting small amounts of the duo under the skin of animals at the Animal Resources Center. These same experiments will be used to evaluate whether the polymer/peptide incites inflammation or other signs that the animals’ protective immune systems are reacting to the presence of the implants.

“We’ve already looked at chronic inflammatory responses to polypyrrole by itself, and haven’t seen any long-term responses,” Schmidt said, noting that the polymer produces less of an immune reaction than PLGA, another polymer that is used in humans for suture material and other purposes.

Schmidt’s lab will also perform more detailed studies to understand which portions of the 12 amino acids that constitute T59 are important for its attachment to the polymer. An amino acid called aspartic acid is already known to be crucial for attachment, but others will likely be found.

The bioengineers also want to see how the two interact after changing the chemical analogs mixed with polypyrrole as a normal part of tweaking the polymer’s electrical conductivity for biomedical purposes.

This conductivity has been important in preliminary experiments Schmidt has done on the regrowth of severed nerves in rats. For these nerve-guidance experiments, the polypyrrole is coated on the inside surface of a tube, or channel, that is sewn into the space between the two ends of a cable-like extension of a nerve that was cut. These cable-like extensions send signals between nerve cells, and polypyrrole’s electrical activity is thought to stimulate healing of a cut extension.

To extend this effort through the grant research, Schmidt’s laboratory will learn how best to use T59 to tether a large protein called nerve growth factor to polypyrrole.

In the future, this material would be coated inside nerve-guidance channels and tested in animal studies of nerve repair. The growth factor is expected to boost repair by stimulating nerve growth from inside the channel, while the polypyrrole connected to it stimulates healing when an electric current is applied.

“We can use this material as a conduit, or an internal band-aid, to promote nerve repair,” Schmidt said, noting that the polypyrrole-containing materials might also hold promise for repair of cartilage, skin or bone because they respond to electric fields. The polymer also could play a role in blood-vessel growth, in drug delivery or in studies of the central nervous system.

When Schmidt’s research expands beyond nerve regeneration, central-nervous-system research is a possible focus. In this case, polypyrrole could serve as a component of electrodes used to monitor the activity of nerve cells in the brain, or to stimulate these cells in diseases like Parkinson’s.

To learn about the Nature Materials research, which was also conducted with colleague Angela Belcher at Massachusetts Institute of Technology, visit Engineers improve plastic’s potential for use in implants by discovering way to link it to biological materials from May 16, 2005.

For more information contact: Becky Rische, College of Engineering, 512-471-7272.