AUSTIN, Texas—Despite the sobering amount of carbon dioxide needing storage to reduce greenhouse gases, funneling the offensive chemical underground remains technologically possible for the oil industry, says Dr. Steven Bryant, associate professor of petroleum and geosystems engineering at The University of Texas at Austin.

|

|

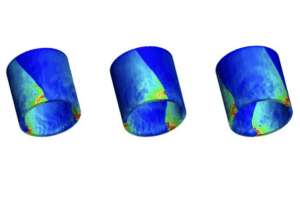

Dr. Steven Bryant, associate professor of petroleum and geosystems engineering, holds two halves of a fractured sample of wellbore cement. Confining the two halves together at pressures similar to those in formations deep below the Earth’s surface provides a laboratory model of one type of pathway conceivably allowing carbon dioxide to escape the storage formation.

|

|

Photo: Erin McCarley

|

His feasibility study proving the capability and documenting the technical requirements for storing carbon dioxide underground, as well as the parallels to current processes within the oil industry, appears in the September issue of the Journal of Petroleum Technology.

“The oil industry has decades of experience moving large amounts of gas underground and above ground,” Bryant said. “In fact, capturing carbon dioxide from fixed sources, such as coal-fired and gas-fired power plants, and injecting it into geological formations mimics many of the processes already undertaken to produce fossil fuels.”

Few other industries deal with fluid volumes of this size, he said. The industry could respond with an ‘off-the-shelf’ geological-storage service in a short time—a key advantage given the urgency of the problem.

“This is not to dismiss the very real difficulty of finding and developing the financial and human resources for such an enterprise, nor of building the necessary infrastructure,” he said.

Now in his fourth year of investigating the key physical processes associated with sequestering carbon dioxide, Bryant has found that injecting carbon dioxide into formations deep within the Earth’s crust is one of the few technologies that can be implemented rapidly enough and at a large-enough scale to mitigate greenhouse gas emissions. He directs the Geologic CO2 Storage Joint Industry Project in the Center for Petroleum and Geosystems Engineering.

Bryant’s research was featured in the Special Report on Carbon Dioxide Capture and Storage released by the Intergovernmental Panel on Climate Change in spring 2007. The panel highlighted his findings for the “inject low and let rise” strategy of maximizing the secure, long-term immobilization of stored carbon dioxide.

“But doing this is going to require society—industry, government, consumers—to make a tremendous investment of resources, both financial and human,” he said. “This challenge motivates the current goals of our Joint Industry Project: to train a new breed of ‘carbon management engineers’ to design, construct, operate, optimize and regulate large-scale carbon dioxide sequestration projects, and to carry out research that makes this technology as cost-effective and routine as possible.”

Nevertheless, Bryant remains realistic about the prospects for his industry to create clean air.

“The public perception of the ‘fairness’ of the industry’s role in geologic storage may distort or even overwhelm a rational evaluation of the challenges,” he noted in the report. “Although it provides more than half of the energy needed to fuel the global economy, the oil and gas industry has never garnered much public sympathy for its efforts. Ironically, being uniquely qualified to help save the planet may not improve the industry’s image.”

Bryant holds the George H. Fancher Centennial Teaching Fellowship in Petroleum Engineering. His paper appeared as part of the Distinguished Author Series of the Journal of Petroleum Technology.

For more information contact: Becky Rische, Cockrell School of Engineering, 412-471-7272.