The Advanced Energy Consortium, a research consortium managed by the Bureau of Economic Geology at The University of Texas at Austin’s Jackson School of Geosciences, has issued a request for proposals (RFP) to develop micro- and nanoscale technology for enhanced reservoir characterization and hydrocarbon detection in conventional oil and gas reservoirs with the ultimate goal of increasing hydrocarbon recovery from known fields.

The consortium expects to fund 6 to $7 million in grants this year on micro- and nanosensor research and enabling technologies.

The consortium’s primary goal is to fund research that leads to the development of intelligent subsurface micro- and nanosensors that can be injected into oil and gas reservoirs to help characterize the space in three dimensions, identify fluids and locations, and improve recovery of existing and new hydrocarbon resources. By leveraging existing surface infrastructure, the technology will minimize environmental impact.

Geoscientists think they can extract more oil and gas by improving understanding of the chemical and physical characteristics of the host reservoirs and their hydrocarbon distribution. Under current technology, 60 percent of oil typically remains underground even after secondary and sometimes tertiary attempts to recover the resource.

The privately funded consortium has nine members: BP America Inc., Baker Hughes Incorporated, ConocoPhillips, Halliburton Energy Services Inc., Marathon Oil Corp., Occidental Oil and Gas, Schlumberger, Shell and Total. Rice University, which has extensive nanotechnology expertise, is a collaborative technical partner.

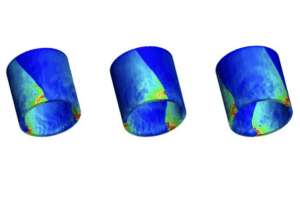

The consortium intends to develop micro- and nanoscale sensors that will measure the chemical and physical properties of reservoir fluids and rocks beyond the well bore, the three-dimensional distribution of these reservoir fluids (petroleum and natural gas) and rocks (layering and compartmentalization), and the dynamic (4-D) paths of fluids as they move through the reservoir.

A challenging aspect of the application is the harsh downhole environment: conventional reservoir temperatures typically range from 100 to 350°F and pressures from 5,000 to 20,000 pounds per square inch. Nanosensors would be surrounded by charged rock surfaces and complex fluid mixtures that could include oil, hydrocarbon gas, water, acids, alkalis, tars, brines, nitrogen, carbon dioxide and hydrogen sulfide. Conventional microelectronic sensors cannot operate under these conditions. The consortium seeks research proposals that address sensor development, emplacement, recovery, protection, location, power, telemetry and data management.

The RFP and supporting documentation can be found online.