President Barack Obama and the U.S. Department of Defense (DOD) today announced the establishment of the Digital Manufacturing and Design Innovation Institute (DMDI), a new $320 million research collaboration that includes The University of Texas at Austin’s Cockrell School of Engineering.

The Institute will be funded by a $70 million grant from the DOD, along with $250 million in contributions from industry, academia, government and community partners. DMDI, which will be known as the Digital Lab for Manufacturing (Digital Lab), will be housed in Chicago-based UI Labs, with a network of manufacturing partners and research sites across the United States.

UT Austin’s Cockrell School is one of only six engineering schools across the nation to be selected to be an integral partner in the Digital Lab. UT Austin will serve as the lead team for universities, companies and research institutions in Texas. In all, the Digital Lab has 40 industry partners and more than 30 partners from academia, government and community organizations.

The investment is part of President Obama’s vision to re-invigorate U.S. manufacturing, creating new jobs and economic development and spurring future innovation. The grant was formally awarded on Tuesday, Feb. 25, at a White House ceremony. The Digital Lab will be a self-sustaining research institute following the initial five-year federal investment.

The Digital Lab will serve as the nation’s flagship research institute for digital manufacturing, applying cutting-edge technologies to reduce time and cost of manufacturing, strengthen the capabilities of the U.S. supply chain and reduce acquisition costs for DOD. The lab will both develop and demonstrate digital manufacturing technologies and deploy and commercialize these technologies across key manufacturing industries.

“The Digital Lab is an opportunity for UT Austin to work with industry and government to swiftly bring technology to manufacturing shop floors, create jobs and strengthen the nation’s industry,” said UT Austin President Bill Powers. “We are thrilled that the research and technologies developed at UT Austin will help shape the future of digital manufacturing for the nation and the state of Texas.”

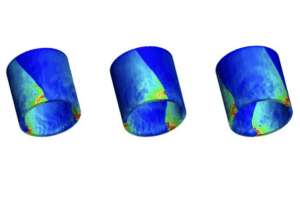

Digital manufacturing is the use of an integrated computer-based system composed of simulation, 3-D visualization, analytics and various collaboration tools to create product and manufacturing processes simultaneously.

Cockrell School mechanical engineering professors Joseph Beaman and Steve Nichols have provided leadership in planning the Institute’s areas of focus, and they will direct the Digital Lab efforts at UT Austin. The university has numerous faculty members and researchers contributing to the area of digital manufacturing, including experts from UT Austin’s Advanced Manufacturing and Design Center, IC2 Institute and the Institute for Computational Engineering and Sciences.

“Driving the field of digital manufacturing is the need to address the cost and time issues faced by manufacturers across all industries, especially those dealing with complex manufacturing systems and parts such as the automotive and aerospace industries,” Beaman said. “Up to 85 percent of a manufacturing system’s total life cycle cost is incurred during the design and development phase.”

For instance, designing and making critical parts for the aerospace industry often requires repeated adjustments to meet specifications. One of the goals of this project is to completely eliminate this type of iterative assembly, Beaman said.

The Digital Lab’s areas of focus will include advanced analysis, intelligent machining and advanced manufacturing enterprise, which are agile and robust manufacturing strategies and integrated capabilities that dramatically reduce the cost and time of manufacturing.

Although UT Austin’s Digital Lab project is yet to be determined, it will probably focus on advanced manufacturing analysis, Beaman said. “UT Austin is in a unique position to help move manufacturing information and prediction upstream by expanding the scope of highly successful analysis design tools,” he said.

One example of a successful analysis design tool is a computer model that can be combined with real-time 3-D measurements, allowing for virtual tweaks and testing before equipment or prototypes are put on the assembly line.

Because of this partnership “UT Austin will play a key role in developing digital manufacturing systems for the nation alongside industry and government,” Beaman said.

The Digital Lab’s industry partners include, but are not limited to, General Electric, Rolls-Royce, Procter and Gamble, Dow, Lockheed Martin, Southwest Research Institute and Siemens.