Researchers at the Cockrell School of Engineering have built the smallest, fastest and longest-running tiny synthetic motor to date. The team’s nanomotor is an important step toward developing miniature machines that could one day move through the body to administer insulin for diabetics when needed, or target and treat cancer cells without harming good cells.

With the goal of powering these yet-to-be invented devices, UT Austin engineers focused on building a reliable, ultra-high-speed nanomotor that can convert electrical energy into mechanical motion on a scale 500 times smaller than a grain of salt.

The nanomotor is just one example of the innovative health-related devices and advancements occurring at the Cockrell School. Take a look at some high-tech creations developed by engineering researchers to improve lives and provide better health care options in the future.

World’s Smallest, Fastest Nanomotor

DEVICE: A motor smaller than a human cell that could help advance the study of drug delivery

Mechanical engineering assistant professor Donglei “Emma” Fan led a team of researchers in the successful design, assembly and testing of a high-performing nanomotor in a nonbiological setting. The team’s three-part nanomotor can rapidly mix and pump biochemicals and move through liquids, which is important for future applications. The team’s study was published in the April issue of Nature Communications.

Fan and her team are the first to achieve the extremely difficult goal of designing a nanomotor with large driving power.

With all its dimensions under 1 micrometer in size, the nanomotor could fit inside a human cell and is capable of rotating for 15 continuous hours at a speed of 18,000 RPMs, the speed of a motor in a jet airplane engine. Comparable nanomotors run significantly more slowly, from 14 RPMs to 500 RPMs, and have only rotated for a few seconds up to a few minutes.

Looking forward, nanomotors could advance the field of nanoelectromechanical systems (NEMS), an area focused on developing miniature machines that are more energy efficient and less expensive to produce. In the near future, the Cockrell School researchers believe their nanomotors could provide a new approach to controlled biochemical drug delivery to live cells.

To test its ability to release drugs, the researchers coated the nanomotor’s surface with biochemicals and initiated spinning. They found that the faster the nanomotor rotated, the faster it released the drugs.

“We were able to establish and control the molecule release rate by mechanical rotation, which means our nanomotor is the first of its kind for controlling the release of drugs from the surface of nanoparticles,” Fan said. “We believe it will help advance the study of drug delivery and cell-to-cell communications.”

Detecting Cardiovascular Conditions More Clearly

DEVICE: A catheter that uses advanced imaging to detect arterial build-up

Researchers in biomedical engineering professor Stanislav Emelianov‘s Ultrasound Imaging and Therapeutics Research Laboratory are analyzing and testing tools that may better detect plaques in coronary arteries and their vulnerability to induce life-threatening conditions. Combining ultrasound and photoacoustic imaging techniques, their prototype catheter rotates to capture images in multiple directions to provide information about the artery structure and composition, creating a more clear and complete picture of the artery and the plaques that may be in it, and ultimately offer guidance for better treatment outcomes.

Treating Patients Through Wearable Electronics

DEVICE: An electronic “tattoo” to measure information and deliver medicine

For her most recent development, Nanshu Lu, NSF CAREER Award winner and assistant professor in aerospace engineering and engineering mechanics, has created a first-of-its kind device that can measure and store data about a person’s movements, receive diagnostic information and deliver medicine, all through the skin. Lu invented the geometrical configuration of the circuit to allow the wearable electronics to expand and compress. Made up of stretchable nanomaterials, the electronic “tattoos” and other bio-integrated electronics are revolutionizing health care.

Related: High-Tech Tattoos Redefine Health Care Solutions (Know)

Bringing Robotics Into Rehabilitation

DEVICE: A robotic hand exoskeleton to assist in rehabilitation

Influenced by his own hand injury, mechanical engineering assistant professor Ashish Deshpande set out to explore how robotic devices could safely assist patients in their physical therapy. In his ReNeu Robotics Lab, he and a team of students are designing a robotic hand-wrist exoskeleton that delivers repetitive and intensive rehabilitative movements that can restore functional capabilities of the wrist, hand and fingers. This and other devices may eventually help physical therapists monitor patients’ progress more precisely and keep patients more engaged.

Related: Finding the right Niche for Human-Friendly Robotics (Cockrell School); The Robots Are Coming! (Alcalde)

Cooling the Body Faster and More Effectively

DEVICE: A noninvasive, portable mechanism to cool the body’s core

Using a cooling pad and a battery-powered thermoelectric system essentially, a small refrigerator biomedical engineering professor Ken Diller has created a compact portable body-core-cooling device that artificially simulates blood flow through our most effective heat transfer portals: the palms of our hands and the soles of our feet. Most significantly, Diller’s mechanism provides a noninvasive solution to cooling the body’s core quickly during medical events such as strokes, brain injuries and heart attacks. Eventually, the device could be housed on airplanes and used by EMS professionals in the field.

Filling a Void in Commercial Prosthetic Device Options

DEVICE: A customized prosthetic foot to improve the lives of amputees

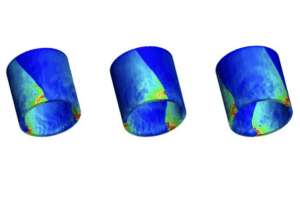

Mechanical engineering professor Rick Neptune is using a cutting-edge technology developed at UT Austin selective laser sintering (SLS) to help improve the quality of life for lower-limb amputees. Beginning with a 3-D computer model, the SLS process uses a high-powered laser to build the design out of layers of powder. In Neptune’s case, the end product is a sturdy yet flexible prosthetic device that is tailored to the amputee. He and his students are currently creating customized prosthetic and orthotic devices for injured soldiers.

Related: Building Prosthetics for Injured Veterans (Cockrell School, with video by Longhorn Network)

This story is part of our yearlong series “In Pursuit of Health,” covering medical news and research happening across the university.