AUSTIN, Texas — To combat the extreme environmental toll of major oil spills, researchers at The University of Texas at Austin have created a technology that could significantly improve cleanup capabilities compared with current methods.

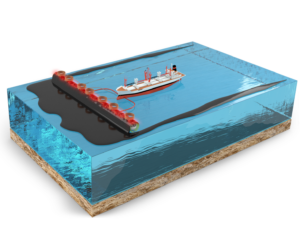

The new technology uses a dual-layer mesh roller coupled with an induction heating technique, with material properties that allow it to separate oil from water and then remove that oil from the ocean with high efficiency and throughput. In experiments, the researchers showed the potential to retrieve up to 1,400 kilograms of viscous oil per square meter per hour, which is about 10 times better than the way oil is cleaned up today.

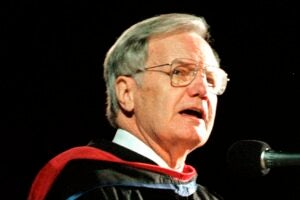

“When you have a widespread oil spill in the ocean, it slowly diffuses into the water, so how quickly and efficiently you can retrieve the oil has a major impact on the marine environment,” said Guihua Yu, a professor of materials science in the Cockrell School of Engineering’s Walker Department of Mechanical Engineering and Texas Materials Institute.

The findings are published in Nature Sustainability.

In practice, the rollers could be built to different sizes to deal with oil spills. Boats would pull them across a spill area, where they could complete cleanup operations in a day or two, compared with the weekslong efforts that current techniques require.

Oil’s viscous nature makes it challenging to separate from water. The gel-coated mesh roller can selectively adhere oil at the interface of the cold seawater on the bottom side and separate viscous oil/water mixtures at the top side of the roller. Then, a device in between the two layers captures the now-separated oil.

The researchers applied non-contact induction heating to the top layer of the roller to supercharge the reaction that separates oil from water. In experiments, the researchers achieved over 99% oil-water separation efficiency. That means the collected oil could also be recycled and reused.

Yu’s research has touched on other areas of sustainability, such as generating gels that can pull water from the air and significant improvements to soil and farming practices. He said he was inspired to pursue this research by the Deepwater Horizon spill. The 2010 incident off the Gulf Coast was the largest U.S. oil spill in history, with more than 100 million gallons of oil leaked, forever altering the ecosystem there. Crews tried different ways to clean up the spill, but the impact remains present to this day, with some estimates indicating only about a quarter of the oil was recovered.

This got Yu thinking about oil spill cleanup technology. He looked at commonly used cleanup methods, such as skimmers, and what he found was a major need for a modernized way to efficiently pull oil out of water with much higher throughput.

“Most of the methods in use today rely on decades-old technology,” Yu said. “I just thought we should be able to do better than that.”

Up next, the researchers will focus on scaling the technology. They are open to working with industrial partners on scaling and field tests.

The research was funded by The Welch Foundation and The Camille & Henry Dreyfus Foundation. The project team includes Ke Yan and Fei Zhao of the Materials Science and Engineering Program in the Walker Department of Mechanical Engineering/Texas Materials Institute and professors Lijia Pan and Yi Shi from Nanjing University in China. The research team also worked with professor Kishore Mohanty of UT Austin’s Hildebrand Department of Petroleum and Geosystems Engineering to procure raw viscous oil for the project.