Pioneering students, hands-on tech and the space to create and collaborate — that’s the foundation of the Longhorn Maker Movement. From traditional soldering and woodworking to advanced 3D printing and robotics, the “maker” activities available on campus are as varied as the students driving the Maker culture. The students are do-it-yourself, engineering-centric creative thinkers and problem solvers.

UT Austin has been a leader among universities when it comes to providing makerspace opportunities. These makerspaces inspire students, expand course engagement, provide hands-on learning opportunities and spur both innovation and entrepreneurship.

But being a Maker is not just for engineering students. All over the Forty Acres, the Maker Movement has found massive interest across many disciplines.

Making has long been an integral part of the design and planning education at the School of Architecture. In the 1970s, the first student-focused “open-access shop” was spearheaded by the school. The space would be known today as a makerspace.

“Making creates better designers,” says Eric Hepburn, the School of Architecture’s information technology director who also manages the school’s digital fabrication efforts. “Having access to these tools lets students engage with real materials, take on real projects and make real things.”

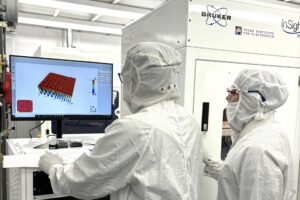

The Cockrell School of Engineering recently launched The Longhorn Maker Studio, fully stocked with 3D printers, laser cutters and other tools. A student lounge adjacent to the Longhorn Maker Studio even features a 3D printing vending machine called The Innovation Station, where anyone with a UT EID can come and print out their own Hook ‘Em souvenir or anything else they can imagine.

“Our goal is really hands on. We want people to make things for themselves,” says Desiderio Kovar, a mechanical engineering professor and faculty director of the Longhorn Maker Studio. “It’s really a better way to teach. Rather than lecturing on some theoretical topic, now we start with a problem, and then you can work in the theory.” The video below takes an in-depth look at the tools and training available in The Longhorn Maker Studio

Launched in the spring of 2014, the Digital Fabrication Lab provides undergraduate and graduate students in the Department of Art and Art History in the College of Fine Arts with tools to find inspiration and create art in all types of media.

“This is the leading edge of fabrication techniques in many disciplines but especially in the creative fields,” says Jack Risley, chair of the Department of Art and Art History. “It’s important our students not only have access to but also a familiarity with these techniques. These tools are becoming ubiquitous and will be part of the landscape of our students’ lives and professional careers.”

The Center for Arts and Entertainment Technologies in the College of Fine Arts and the Fine Arts Library was recently awarded a grant from The Hearst Foundations to help create a common makerspace called The Foundry, where students can create 3D objects, videos, apps and other creative projects in the digital arts.

“The Foundry will support new collaborations across disciplines and give students the hands-on technological skills and knowledge they need to succeed as artists and entrepreneurs,” said Bruce Pennycook, director of the center.

In addition to UT Libraries role in setting up The Foundry, they’ve also recently launched the Learning Commons in partnership with The College of Liberal Arts. The new space includes five technology-rich classrooms for adaptive, collaborative learning techniques, a 44-seat media lab with high-end software, and consultation and meeting areas available to all students, as well as faculty who want to incorporate digital literacy into their courses.

The Blanton Museum of Art has gotten into the Maker act as well with WorkLAB Satellites, mobile workstations incorporated into the museum. The workstations give visitors a chance to find inspiration in the museum and then create art.

“Traditionally a viewer walks through galleries and museums, at a slow pace, to stop and engage with the art. But WorkLAB Satellites offers a point of refuge where one can spend time and interact,” says Leslie Mutchler, the artist who designed the WorkLAB Satellites. “Satellites is designed so that someone with a strong arts background won’t be bored by the materials and prompts, and also for the non-artist to come and feel comfortable making and exploring.”

The university has “championed a ‘Maker culture’ for more than three decades” and continues to make significant investments in maker spaces while “developing 21st century tools that empower student entrepreneurs and propel the Maker Movement,” UT President Gregory L. Fenves (while serving as executive vice president and provost) wrote in a June 2014 letter to President Barack Obama on the occasion of the White House Maker Faire.

“Across UT Austin, students have become passionate participants in the Maker Movement, and faculty, researchers and industry partners have established Texas as a destination for innovation and entrepreneurship,” Fenves wrote to President Obama. “We look forward to continuing to play an integral part in the manufacturing economy by inspiring and educating the next generation of Makers.”

The Longhorn Maker Movement. That’s how we change the world!